Humans have been dyeing fabrics for centuries. The ancient Romans used urine, natron (sodium carbonate), and iron alum as mordants for dyeing wool, linen, and tree cotton (Gossypium arboreum).

The murex shellfish (Bolinus brandaris) was used for the Tyrian or Imperial red-purple dye reserved for emperors. Its cousin, the banded dye murex (Hexaplex trunculus) was used for Royal blue-purple dye that was also reserved for the aristocracy. Both of these dyes worked by exposure to sunlight. The darker the color, the more valuable they were.

Saffron (still prohibitively expensive) was used for yellow and reserved for Vestal virgins and matrons. Indigo, the fermented plant dye imported from India, was also an expensive blue dye. Kermes or Crimson was an expensive red dye obtained by fermenting the cochineal insect imported from Europe.

Weld is a European plant that was used to make a cheap yellow dye. Madder root (russeus) is another European plant that was used for red, orange, and brown. Woad was used as a cheap source of blue (venetus). Green (pirineus) was produced from lichens. Iron (ferrous sulphate) made by soaking iron in water was used to make black and to change other colors. It is the mordant in iron (oak) gall ink. Unfortunately, the acidic nature of iron is corrosive to natural fabric.

The quick method is to use a fiber reactive dye. Procion MX is perfect.

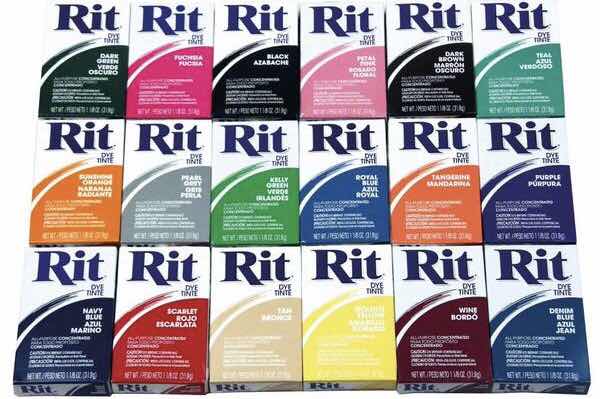

Rit dye may be better for learning. Rit now has all their dye color formulas on an iPhone app. They are no longer available on their website.

| Dye | Dry Fabric Weight | Salt | Water |

| 1/2 Tbsp | 1 Ounce | 3/4 tsp | 3 Cups |

| 1 Tbsp | 2 Ounces | 1/2 Tbsp | 6 Cups |

| 2 Tbsp | 1/4 Pound | 1 Tbsp | 12 Cups |

| 4 Tbsp | 1/2 Pound | 2 Tbsp | 1 Gal + 8 Cups |

| 4 Ounces | 1 Pound | 1/4 Cup | 3 Gallons |

| 6 Ounces | 1-1/2 Pounds | 1/2 Cup | 3 Gal + 3 Quarts |

| 8 Ounces | 2 Pounds | 1 Cup | 6 Gallons |

| 10 Ounces | 2-1/2 Pounds | 1-1/2 Cups | 6 Gal + 8 Cups |

| 12 Ounces | 3 Pounds | 2 Cups | 8 Gallons |

| 14 Ounces | 3-1/2 Pounds | 2-1/2 Cups | 8 Gal + 3 Quarts |

| 16 Ounces | 4 Pounds | 3 Cups | 9 Gallons |

A great way to test a dye batch is to mix 3 cups of boiling water with 3/4 teaspoons of salt and pour it into a quart size mason jar. Add a 1/2 tablespoon of liquid dye. Screw on the lid and shake to distribute. Remove the lid and place a strip of washed fabric into the dye, leaving a piece to hang over the lip. Screw the lid back on securing the fabric. Time how long the fabric stays in the dye. Rinse, wash, rinse again and dry the fabric as usual.

If the color is too light, double or triple the amount of dye and salt in the same amount of water and test it again. If it's too dark, remove 1-1/2 cups of the bath and add 1-1/2 cups of boiling water.

Urea helps dye to dissolve and extends the life of dye in the bath. You'll have to grind this to a powder. Available from Making Cosmetics for $11.10/4 oz.

Sodium sulfate (Glauber's or Dyer's Salt) is a mordant. Johann Glauber was the first to produce the salt from Hungarian spring waters. The naturally occurring salt is called mirabilite. Glauber's salt is water soluble, has a salty, bitter taste, and is sometimes used in medicine as a mild laxative; it is also used in dyeing. It is a non-iodized salt in flake form that dissolves quickly in water. Get it here.

Calsolene Oil is used as a wetting agent. It is mixed with hydrophobic pigments to predisperse them and make a paste. It is used in a 1:1 ratio with pigment. It's available from Dharma Trading for $3.65.

Sodium lauryl sulfate (Dawn dishwashing detergent) is a surface tension breaker that allows water and pigment to penetrate fibers.

Sodium carbonate, an alkaline salt, (also known as washing soda, soda ash, soda ash fixative, or soda ash activator) is the sodium salt of carbonic acid. In dyeing with fiber-reactive dyes, sodium carbonate is used to ensure proper chemical bonding of the dye with cellulose plant fibers (cotton, bamboo, hemp, and flax). However, it shortens the life of dye in a dye bath. It is used to fix dye to the fabric. It is also a water softener. If you have hard water (calcium or magnesium deposits), add 1 cup of washing soda water (1/8 cup Washing soda dispersed in 1 gallon warm water) to every vat cycle--wash, dye and soak.

Methyl alcohol is a dye fixative used to improve wash fastness. It enhances the action of washing soda for dark colors. Add 1 oz per pound of fabric. For solid colors, add to hot water before washing and soak for 30 minutes. For tie dye and batiks, add to a cool final rinse for 15 minutes after washing. For best results, water should have a pH of 7. You'll have to order this from Dharma Trading.

Do not use aluminum, copper, or cast iron as a dye vat. You must use a non-reactive metal. Stainless steel is the best.

Materials

Stainless steel pot (dye vat)

Fabric claw hooks

Mini mixer with immersion attachment

Glass cup for dissolving dye

Long wood or plastic spoon

Glass measuring cups

Textile Detergent

Calsolene Oil (disperses dye evenly)

Urea (makes dye dissolve easier)

Glauber's Salt (mordant)

Fiber Reactive Dye

Washing Soda (water softener & dye fixative)

Methyl alcohol

Stainless steel pot (dye vat)

Fabric claw hooks

Mini mixer with immersion attachment

Glass cup for dissolving dye

Long wood or plastic spoon

Glass measuring cups

Textile Detergent

Calsolene Oil (disperses dye evenly)

Urea (makes dye dissolve easier)

Glauber's Salt (mordant)

Fiber Reactive Dye

Washing Soda (water softener & dye fixative)

Methyl alcohol

For 1/2 yard of fabric:

1-1/2 Gallons warm water

1/2 Tbsp Dye for medium color

1 Tbsp Dye for intense color

1-1/2-2 Tbsp Dye for dark color

1-1/2 cup Glauber's salt, 3 for dark colors

1/2 Tbsp Urea

1/2 Tbsp. Washing Soda dissolved in 2 cups warm water

1/2 tsp. Dawn

For 1 yard of fabric:

3 Gallons warm water

1 Tbsp Dye for medium color

2 Tbsp Dye for intense color

3-4 Tbsp Dye for dark color

3 cups Glauber's salt, 6 for dark colors

1 Tbsp Urea

1 Tbsp. Washing soda dissolved in 2 cups warm water

1 tsp. Dawn

1) Heat water in dye vat (stainless steel pot).

2) Dissolve all powders in hot water before adding to dye vat.

3) Add Dawn, washing soda water, and salt water to hot dye water in vat.

4) Mix 1 tablespoon urea in 1 cup of warm water.

5) Mix dye with 1 teaspoon of calsolene oil and mash into a paste.

6) Add dye to urea and mix into a thick slurry. A mini mixer with a submersion attachment will make this easier.

7) Strain through a fine mesh paint strainer. Deposit lumps back into the cup. Add a little of the dye and mash the lumps. Strain again. Continue until the lumps are gone.

8) Pour the dissolved dye into the water.

9) Add pre-washed wet fabric.

10) Stir gently, but frequently for 20 minutes.

11) Continue stirring occasionally for 30 minutes for light colors or 1 hour for dark colors.

12) Rinse in cool water until it runs clear. If you intend to batik after the first dye, skip step 12 until after you're finished. Move on to the Batik tutorial.

13) For dark colors and reds, add 1 oz Methyl alcohol per pound of fabric. For solid colors, add to hot water before washing and soak for 30 minutes. For best results, water should have a pH of 7.

14) Wash in hot water with textile detergent. Dark colors and black may need a second washing.

15) Rinse in cool water.

16) For tie dye and batiks, add 1 oz Methyl alcohol per pound of fabric to a cool final rinse for 15 minutes after washing. For best results, water should have a pH of 7.

17) Soak in cool water and Milsoft to soften the fabric after dyeing. Rinse with cool water.

18) Hang fabric to dry.

Mordants

Alum: (Aluminum Potassium Sulfate)

This is the most widely used mordant. Be careful not to use too much with wool, otherwise you will get a sticky feeling that doesn't come out. Prevents fading in cotton.

Calcium Carbonate (chalk) Use for madder. Add ammonia for silk or wool.

Copper: (Copper Sulfate) This mordant is used to bring out the greens in dyes. It will also darken the dye colors, similar to using tin, but is less harsh.

Citric Acid: Used in natural dyeing to increase acidity of dye baths. Also used in place of Acetic Acid (vinegar).

Iron: (Ferrous Sulfate) Dulls and darkens dye colors. Using too much will make the fiber brittle.

Fructose Granules Use for fermentation with indigo & woad.

Glauber's Salt: (Sodium Sulfate) Used in natural dyes to level out the bath. Also use in chemical dye. Cotton.

Pickling Lime Use to neutralize acid with indigo & woad.

Spectralite: (Thiourea Dioxide) This is a reducing agent for indigo dyeing.

Tannic Acid (chestnut bark) Increases light fastness.

Tartaric Acid: A must for cochineal. This mordant will expand the cochineal colors.

Tin: (Stannous Chloride) Tin will give extra bright colors to reds, oranges and yellows on protein fibers. Using too much will make wool and silk brittle. To avoid this you can add a pinch of tin at the end of the dying time with fiber that was pre-mordanted with alum. Tin is not commonly used with cellulose fibers.

Natural Dyes

Alkanet (purple, mauve, lavender)

Annatto (yellow-orange, cream)

Bitumen (yellow-orange, cream)

Brazil Wood (yellow-orange, cream)

Chicory (yellow-orange, cream)

Cochineal/Carmine (wine, fuchsia, pink)

Coffee (deep brown)

Cutch (brown, khaki, peach)

Fustic liquid (gold)

Henna (tan, ivory)

Himalayan rhubarb (olive)

Indigo (blue)

Kamala (Indian yellow or brown warss) memecylon tinctorium

Lac (bright pink)

Logwood (violet, lilac)

Madder (red, coral)

Mahogany Wood (red, coral)

Myrobalan (khaki)

Osage Orange (yellow)

Pomegranate (navy, tan)

Quebracho rojo (pale red)

Quebracho moreno (orange)

Sandalwood (rust, orange, peach)

Saxon Blue Indigo liquid (aqua blue)

Tea (light brown)

Walnut hulls and Wood (brown)

Weld (lime green)

Woad (green)

Mushrooms

These mushrooms cannot be purchased; they must be foraged. Some are also toxic and must be handled with gloves. They can be used for dye and pigment. Fresh mushrooms result in a vibrant color. Dried mushrooms result in a pale or muted color. Alum and iron are used as mordants. Alum results in a bright color. Iron results in a deep color. Water pH and time varies. The North American Mycological Association has an extensive list of mushrooms used for dye.

Phaeolus schweinitzii (found at the base of Douglas Fir): pH 5, 15 min, alum = light gold, 20 min = deep gold

Gymnopilus spectabilis (found in clusters on dead Bishop Pine): pH 5, 20 min, alum = medium gold

Dermocybe malicoria (found at the base of Pine): pH 4, 20 min, alum = medium-deep orange; iron = cinnamon red-brown

Hypomyces lactifluorum (found at the base of Pine): pH 4, 20 min, alum = yellow-orange; iron = deep yellow-orange

Dermocybe phoenicea var. occidentalis (found at the base of Bishop Pine and mixed conifers): Fresh, pH 3.5, 20 min, alum = orange-red, iron = medium brown; pH 5, alum = crimson, iron = maroon; pH 8.5, alum = coral, iron = tan

Dry, pH 3.5, 20 min, alum = peach, iron = straw yellow; pH 5, alum = light red, iron = deep brown, pH 8.5, alum = light peach, iron = light straw

Dermocybe semi-sanguinea (found at the base of Bishop Pine and mixed conifers): Whole, pH 5, 10 min, alum = true red, iron = umber; pH 8, alum = muted, iron = muted

Caps only, pH 5, 15 min, alum = deep true red, iron = espresso, pH 8, alum = muted, iron = muted

Tapinella or Paxillus atrotomentosa (found at the base of Bishop Pine and mixed conifers): pH 5.5, 10 min, no mordant = medium brown, iron = deep green, alum = violet, pH 6.5, alum = deep violet

Omphalotus olivascens (found at the base of hardwood stumps): pH 5.5, 3.5 seconds, no mordant = deep plum, 55 seconds, no mordant = purple, 3 seconds, alum = deep purple, 17 seconds, alum = lilac, 55 seconds, alum = lavender

Hydnellum peckii (found at the base of hardwood stumps): pH 9, 20 min, no mordant = pale green, alum = khaki, alum + washing soda = blue-green, iron = deep green

Sarcodon imbricatus (found at the base of hardwood stumps): Frozen, pH 5.5, 20 min, no mordant = pale green, alum = medium green, iron = dark green

Dry, pH 5.5, 20 min, no mordant = straw yellow, alum = sage green, iron = olive green

Sarcodon laevigatum (found at the base of hardwood stumps): Dry, pH 5.5, 15 min, alum = dark green, iron = deep green

No comments:

Post a Comment