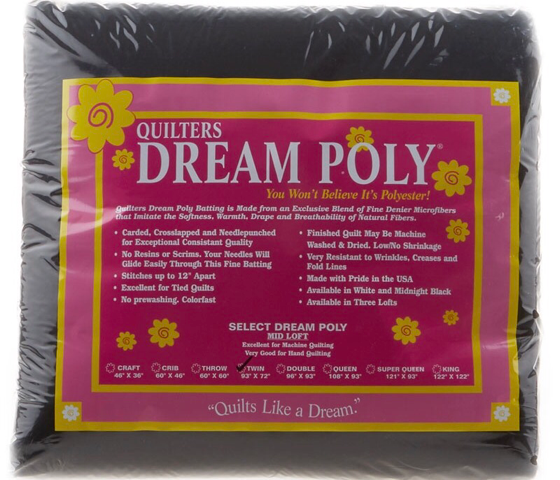

There are different types of batting, but the most commonly used are cotton and polyester. The advantage of cotton batting is that it sticks to cotton fabric and doesn't stretch, reducing the need for basting. It's thin, which makes it easy to quilt by hand or on a domestic machine and there's no bearding. Pieces can be sewn together instead of using batting tape. Polyester requires basting because it slips, stretches and it's prone to bearding. It also requires batting tape because it can't be sewn.

Breathability

The type of batting you choose depends on how the quilt is to be used and who it's for. Animal fibers generate heat and naturally thermo-regulate. Don't use wool batting if someone is allergic to it. Cellulosic fibers breathe and wick moisture. Plastic fibers insulate; they trap heat and moisture.

Cellulosic fibers and silk are best used for babies and hot natured people who are prone to night sweats. Polyester is best for the elderly or cold natured people who are prone to chill.

Fleece and wool trap or generate a lot of heat. Use these battings for winter quilts when the weather is coldest.

Cotton, cotton/poly blend, and polyester can be light to heavy depending on thickness. They're great year round all purpose battings.

Silk and bamboo are cool and light weight. Use these battings for summer quilts when the weather is hot, but you still want to cover up under the a/c.

Sizes

Batting generally ranges in matching quilt sizes.

Baby/Craft 46x36

Crib 46x60

Throw 60x60 (Quilter's Dream)

Twin 93x72

Full/Double 96x93 (Quilter's Dream)

Queen 108x93

Super Queen 93x121 (Quilter's Dream)

King 122x122

Bonding

Battings are bonded in four different ways: needle punched, thermal, scrim and resin.

Needle Punched: barbed needles are punched and twisted into the fibers to tangle them into a strong batting with a felt-like feel and appearance. Needle punched polyester is punched into netting to produce a non-stretchy batting.

Thermal: polyester fibers are heated to melt them together with cotton. This method strengthens the cotton and prevents the polyester from bearding. Quilter's Dream refers to this as Denier to make it sound like it's something special. It isn't! Thermal bonding is the only way to blend polyester with cotton because the two fibers are incompatible and cannot be spun together.

Scrim: a netted polyester layer applied to the batting surface.

Resin: a chemical adhesive sprayed onto the batting. This is the stuff that gums up a needle. Wool is typically spray bonded.

Loft

Loft is the thickness of the batting after it is quilted. It also determines the distance between stitches, how much quilting it can support, and whether it can be quilted by hand. All batting can be quilted by machine, but thicker battings require a long arm or they must be tied. The thicker the batting, the less it can be quilted. High and extra loft battings require a long stitch that may not be aesthetically appealing.

Extra Loft polyester on the left, Wool in the middle, 100% Cotton on the right.

Heirloom Loft Polyester or Traditional/Select Cotton = 3/32"

Recommended for hand or micro quilting 1/4-1" apart.

Request Cotton = 1/16"

Good for hand and domestic machine quilting 1-2" apart.

Mid Loft Ployester or Deluxe Cotton = 1/8"

Good for hand and domestic machine quilting 3" apart.

Supreme Cotton = 3/16"

Good for hand and domestic machine quilting 8-10" apart.

Recommended for trapunto.

80/20 Cotton/Poly = 1/4"

Good for hand and domestic machine quilting 2-4" apart.

Low Loft Polyester = 3/8"

Good for hand and domestic machine quilting 2-4" apart.

Wool = 1/2"

Good for hand and domestic machine quilting 2-3" apart.

Dream Puff Polyester = 1/2"

Good for hand and domestic machine quilting 2-3" apart.

High Loft Polyester = 3/4"

Good for long arm quilting edge to edge designs 4" apart.

Recommended for puffy flannel baby quilts which are the maximum size a domestic machine can handle of this loft.

Extra Loft Polyester = 1"

Must be tied or long arm stitched 6-12" apart.

Recommended for comforters.

Fiber Content

100% Cotton

50/50 Cotton Bamboo Blend

50/50 Alpaca Cotton Blend

80/20 Cotton Poly Blend

80/20 QAYG Printed Batting

70/30 Cotton Poly Blend

60/40 Cotton Poly Blend

25% each Silk/Bamboo/Eucalyptus Tencel/Cotton Blend

90/10 Silk Poly Blend

100% Wool

60/40 Alpaca Wool Blend

100% Fleece

100% Polyester

Fusible

Insulating

Heat Reflective

Flame Retardant

Fiber Fill

Crib Padding

Bead Fill

There are times when I don't have enough batting to complete a project and I have to baste large scrap pieces together. The first thing I do is trim the batting to straighten it. To do this, I use a steel ruler and cut along the edge.

Then I use Batting tape to join the scrap pieces. If you don't have batting tape, cut 1" strips of muslin and adhere them to each end of the batting with washable glue and heat set.

Now, I can finish my project.

No comments:

Post a Comment